Revolutionizing Metal Cutting with Precision Clamping Technology

AME’s exclusive distribution of OTT-JAKOB tool clamping systems in the U.S. sets a new standard for precision and stability in metal cutting. Known for their exceptional durability and reliability, OTT-JAKOB clamping systems ensure that tools remain firmly in place during high-speed operations, minimizing vibration and tool wear. This results in improved accuracy and consistency across machining processes, leading to higher-quality outputs. Additionally, the advanced design facilitates rapid tool changes, which reduces downtime and boosts overall productivity. AME’s ability to seamlessly integrate these systems into existing machinery further enhances their value, making them an essential asset for companies looking to elevate their machining capabilities and ensure long-term operational efficiency.

Exclusive Distributor of OTT-JAKOB Tool Clamping Systems in the US

AME’s partnership with OTT-JAKOB brings cutting-edge tool clamping technology to the U.S. market. The OTT-JAKOB power drawbar and tool retention systems are renowned for their precision, durability, and reliability, ensuring that tools are held firmly in place during high-speed operations. This stability minimizes vibration and tool wear, enhancing the precision and quality of the machining process. The advanced design of OTT-JAKOB systems allows for rapid tool changes, reducing downtime and increasing overall productivity. AME’s expertise in integrating these systems into existing machinery makes it a valuable partner for companies seeking to upgrade their machine tool capabilities, ensuring optimal performance and longer equipment life.

Precision AMLOK® Rod Locks and SITEMA Press Safety Solutions

AME’s offerings in rod locks and press safety are designed to meet the demanding standards of modern industrial applications. The AMLOK® rod locks are engineered to provide secure holding and precise positioning in critical operations, ensuring that components remain in place even under high load conditions. SITEMA’s press safety systems, distributed by AME, add an extra layer of protection by preventing the unintended movement of machine parts, thereby safeguarding both machinery and personnel. These solutions are particularly valuable in sectors where safety and precision are paramount, such as automotive manufacturing, metalworking, and heavy machinery production. AME’s commitment to delivering reliable and effective safety solutions makes it a trusted partner for businesses aiming to enhance operational safety and compliance.

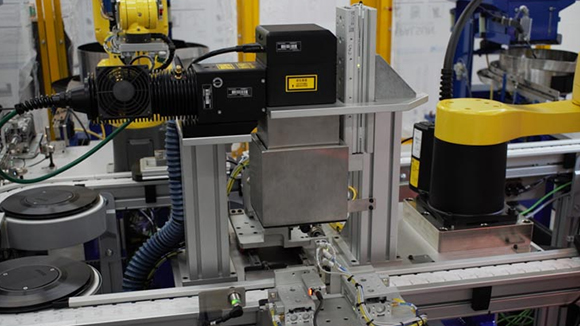

Comprehensive Machine Design and Build Services, Including Automation

AME’s custom machine design and build services cater to companies with unique manufacturing challenges that off-the-shelf solutions cannot address. Their engineering team works closely with clients to develop machines that are tailored to specific production needs, incorporating automation and CNC technology to enhance efficiency and precision. Whether it’s designing a new machine from the ground up or retrofitting an existing system, AME’s approach emphasizes innovation, reliability, and scalability. Their expertise in automation extends to robot machine tending and automated pallet delivery systems, which streamline operations and reduce manual labor. AME’s custom solutions are designed to not only meet current production demands but also to adapt to future needs, providing long-term value for clients.

Advanced Machining Automation Solutions

AME’s machining automation solutions are at the forefront of the industry, enabling manufacturers to achieve new levels of efficiency and productivity. By integrating robotics for machine tending and automated pallet delivery systems, AME helps companies reduce cycle times, minimize human error, and maximize machine utilization. These automation solutions are particularly beneficial in high-volume production environments, where consistency and speed are critical. AME’s systems are designed to be flexible, allowing for easy adaptation to different machining tasks and workflows. The result is a more streamlined production process that not only improves output but also reduces costs and enhances the overall competitiveness of the business. AME’s commitment to advancing machining automation reflects its broader mission to deliver innovative solutions that drive industrial progress.