Machine Health & Performance Management

Bently Nevada, a Baker Hughes brand, provides advanced solutions for machinery protection, condition monitoring, and asset performance optimization, delivering real-time insight into critical rotating equipment through intelligent monitoring systems and System 1™ software. These technologies support predictive maintenance, minimize unplanned downtime, improve safety, and extend asset life. NGEN IT Limited delivers these solutions with expert consultancy, system integration, commissioning, and lifecycle support—helping industries achieve reliable, efficient, and sustainable operations.

Machinery Protection & Asset Safety

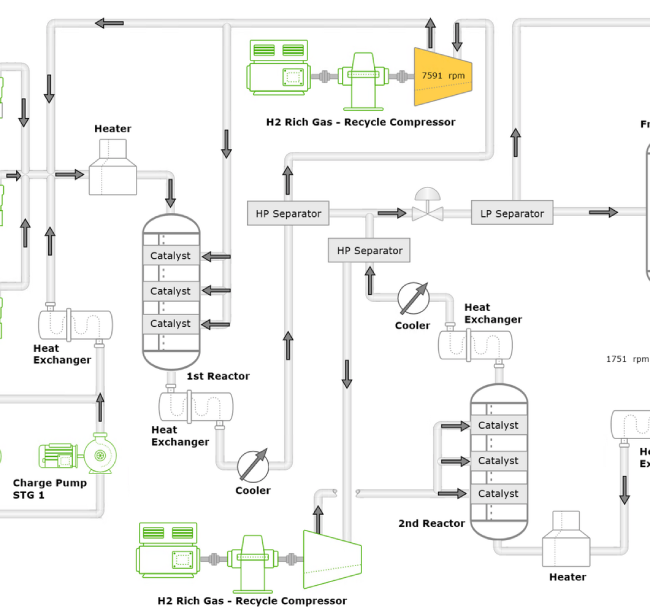

Bently Nevada is globally recognized for its machinery protection systems that safeguard critical rotating equipment such as turbines, compressors, pumps, and generators. These systems continuously monitor machine conditions—like vibration, temperature, speed, and position—to detect abnormal behavior in real time.

By providing early warnings and automatic shutdown capabilities, Bently Nevada solutions help prevent catastrophic equipment failures, protect personnel, and avoid costly production losses. This level of protection is essential in high-risk industries such as oil & gas, power generation, and heavy manufacturing, where equipment failure can have serious safety and financial consequences.

Condition Monitoring & Predictive Maintenance

A core strength of Bently Nevada is its advanced condition monitoring and predictive maintenance technology. Using sensors, data acquisition hardware, and powerful analytics software, operators gain continuous visibility into asset health.

Instead of relying on reactive or time-based maintenance, Bently Nevada enables data-driven maintenance strategies. This allows organizations to:

-

Identify potential faults early

-

Plan maintenance activities more effectively

-

Reduce unplanned downtime

-

Extend the life of critical assets

This approach improves reliability while significantly lowering maintenance and operational costs.

System 1™ Software & Digital Intelligence

Bently Nevada’s System 1™ Condition Monitoring Software is a central platform that transforms raw machine data into actionable insights. It integrates data from multiple assets and monitoring systems, providing engineers and maintenance teams with a single, unified view of equipment performance.

With advanced diagnostics, visualization tools, and analytics, System 1 helps organizations:

-

Analyze machine behavior trends

-

Detect developing faults

-

Improve troubleshooting accuracy

-

Support predictive and reliability-centered maintenance programs

This digital intelligence capability plays a key role in supporting modern industrial digital transformation initiatives.

Lifecycle Services & Global Expertise

Beyond products and software, Bently Nevada offers comprehensive lifecycle services that support customers from system design to long-term operation. These services include system engineering, installation, commissioning, remote monitoring, training, and ongoing technical support.

Backed by Baker Hughes’ global presence and decades of expertise, Bently Nevada ensures customers receive consistent, high-quality support worldwide. This lifecycle approach helps organizations maximize the value of their investment, ensure system reliability, and continuously improve asset performance throughout the operational life of their equipment.