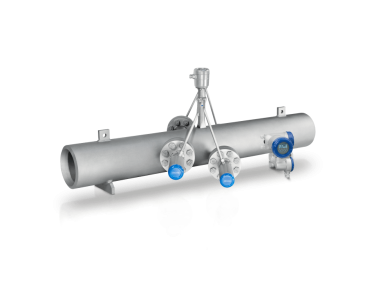

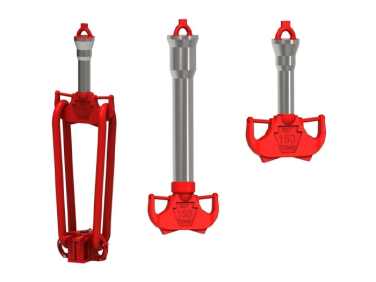

The product features a simple yet robust measuring system that remains virtually unaffected by the chemical and physical properties of various liquids. This versatility makes it suitable for a wide range of applications across different industries. The probe length can reach up to 6000 mm (236 inches), allowing for flexibility in installation based on specific operational requirements.

Designed for accuracy, the system boasts an impressive precision of approximately 2 mm (0.08 inches) when installed vertically, with a repeatability of ±2 mm. This high level of performance ensures reliable measurements under varying conditions. The system can handle process pressures ranging from -1 to 64 bar, making it adaptable to various pressure environments. For temperature resilience, the standard version operates within a range of -50 to 150 °C (-58 to 302 °F), while a high-temperature version extends the limits up to -50 to 250 °C (-58 to 482 °F), catering to more demanding applications.

Additionally, the product incorporates dry-run detection for pumps, enhancing operational safety and preventing potential damage. Its high reliability is further ensured by a permanent fault monitoring function, which continuously checks system performance. Users can choose from various output options, including relay, transistor, NAMUR, contactless electronic switch, and 2-wire configurations, providing flexibility for integration into existing systems.

The system offers numerous process connection options, making it adaptable to different installations. Users can select from plastic, aluminum, or stainless steel housings, depending on their environmental requirements. A wide array of materials is available for wetted parts, including 316L stainless steel, Hastelloy C4, enamel, ECTFE, and PFA, ensuring compatibility with diverse liquids and enhancing longevity. The product is also available with CSA and EEx approvals, underscoring its compliance with safety and regulatory standards, making it a reliable choice for various industrial applications.